Read this article in Français Deutsch Italiano Português Español

The drop-in battery that fools construction machines into thinking it’s an engine

09 June 2025

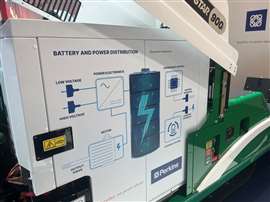

Construction technology is evolving fast – but Perkins’ new battery unit goes a step further. Designed to mimic a diesel engine in both form and function, the system ‘tricks’ machines into thinking it’s business as usual. The goal: to make electrification easier and cheaper for OEMs.

Paul Muller, technical sales manager, Perkins. Image: KHL

Paul Muller, technical sales manager, Perkins. Image: KHL

The new battery electric power unit was first teased by Paul Muller, technical sales manager of UK-headquartered Perkins, at event in London earlier this year.

He was obviously delighted to be able to talk about it fully when Construction Briefing caught up with him at Bauma Munich to discuss the unit that is designed to be ‘plug and play’, meaning that it can be dropped into a machine and work with all the components and electronics as a diesel engine would.

“The power unit itself interfaces in exactly the same way as an engine does. So, we still have a key switch input to it. We have the unit control, and the battery power unit can output an oil pressure signal, even though there’s no oil in it, as some machines need to see the oil pressure before they’ll allow the machine to work,” says Muller, referring to how the unit imitates an engine.

“By mimicking an engine and outputting signal like that, you really have this drop-in replacement for one of our engines. And what that means is that OEMs can continue to build their diesel-powered machines, as there is still a large market there, but it also allows them to have electric as an option.”

Compact drop-in system

The system consists of a Perkins battery along with inverters, motors and on-board chargers packaged up into a compact drop-in system. Inside the box itself is a 64 kilowatt hour, 600 volt battery with a motor that can provide 100-105 kilowatt peak power, 75 kilowatt continuous and a 22 kilowatt onboard charger.

The unit is the same size as Perkins’ 904, 3.6 litre 106 kilowatt engine and while it is technically possible for the unit to be dropped into an existing machine in place of a diesel engine – effectively retrofitting the machine to be zero emissions – it is not the primary idea behind the unit.

The main aim, says Muller, is to give OEMs an easier route to electrify less essential models – those that haven’t yet justified the research and development cost. He adds that, initially, Perkins thought it might be smaller OEMs more towards the start of their electrification journey interested in the solution, but it is actually companies of all sizes.

“There’s been a number of larger OEMs who have a range of electric products already, but they have certain models where there hasn’t been a demand that’s made it worthwhile for them to do it. But this gives them the option to fill out the range with those ones where they haven’t seen the necessity for putting their engineering effort in, if they can have something to drop in without all the work they’d have to do to reconfigure their machines,” reveals Muller.

“They actually see it as opening up some new opportunities for them to fill the range out. They’ve got their core products where they have done electric versions, but they’ve got their less core products where they haven’t – this gives them a chance to do it with less engineering effort. It’s been very interesting actually, that mix, of OEMs.”

High cost of developing electric equipment

As Muller references above, the amount of engineering work required to electrify equipment for the first time is substantial and it was one of the driving forces behind the idea for the power unit.

“We were doing an electrification project with another OEM. They were using our battery, but were sourcing the motors, the inverters themselves. The amount of engineering effort we had to put in, the amount of engineering effort they had to put in, was a lot. It was massively beneficial in the learning we got from it, but it told us that we don’t really want to do this that many times again,” he says with a wry laugh.

2600 Series engine on display at the Perkins press event in London. Perkins says the battery unit mimics how an engine works. Image: KHL

2600 Series engine on display at the Perkins press event in London. Perkins says the battery unit mimics how an engine works. Image: KHL

Once the idea had formed he says that actually building the unit happened quite quickly; it was done in around nine months. “It’s come together really nicely. The team played a really nice game of Tetris to get all the bits into the box. We are really pleased with how it’s turned out.”

Perkins is currently building up more of the battery units with the plan for four prototypes to be used by four different OEMs for testing in different applications over the next six to nine months. The information learned by this testing should provide useful information that could be used to tweak the unit.

When asked what kind of equipment he sees the battery unit being used on, Muller answers, “Pretty much anything; that’s the beauty of it. By mimicking the engine, mimicking the size of the engine, anything that used an engine can use it.”

The first machine to test the unit is a pipe fusion machine, a machine that joins two pieces of thermoplastic pipe together with heat and pressure. Muller says they have already been able to pull a lot of data from that machine including the information that there’s often 50-60% idle time on it which means that, when used with a conventional engine, it is burning a lot of diesel unnecessarily.

In the future they may be a small family of different sized Perkins battery power units. Image: KHL

In the future they may be a small family of different sized Perkins battery power units. Image: KHL

Future electric plans

While, to a certain degree, what comes next will be influenced by what the testing of the four prototypes reveals, Muller already has plans in place for where this concept might go to next.

“Where I’d like this to get to in two or three years is a family of them… two or three different models to cover the range. I don’t think we’re trying to say this is necessarily going to get up into the higher power ranges where today we have the diesel engine though,” he says.

There is also a potential future with add-ons and expansions for the unit – if a machine no longer has need for a fuel tank or something else associated with a diesel engine, what can that extra space be used for?

“We’ve already talked about things like where the ad blue tank used to go, can we use that space for something else as an add-on? How could we offer extra energy, maybe DC fast charging options, but offer those as add-ons rather than as the core product. Because I think the simplicity of the system packaged in the space it is, is a really neat proposition,” he asserts.

At first glance the engine manufacturer Perkins and Tetris have nothing in common but both prize fitting as much into a certain amount of space as possible and making sure that no space is wasted. The electric journey of construction OEMs is no game, but it will be interesting to see if they have been provided with a cheat code for future success with this new unit.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM