TBM for Australia’s biggest renewable energy project

06 December 2021

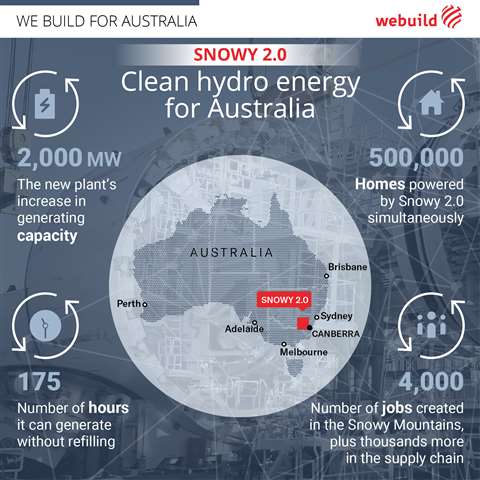

A technologically advanced tunnel-boring machine (TBM) has been commissioned for the development of the Snowy 2.0 pumped-storage scheme, the largest renewable energy project in Australia.

Built specifically for Snowy 2.0 by Germany’s Herrenknecht AG in collaboration with Webuild, the TBM, named after Australian astrophysicist Kirsten Banks, will work on a project that is said to be underpinning Australia’s transition to a renewable energy future.

The project involves linking two existing dams, Tantangara and Talbingo, through 27km of tunnels and building a new underground power station.

TBM Kirsten is a single-shield, open-mode machine designed to deal with hard rock conditions. Its most innovative feature is its ability to excavate at steep angles: up to 9% (five degrees) on declines and up to 47% (25 degrees) on inclines.

With a diameter of approximately 11m, the TBM can excavate up to 30m of rock per day. At 205m in length, it is one of the longest of its kind in operation in the world. It will be responsible for the Emergency, Cable and Ventilation Tunnel, Inclined Pressure Shaft and 2km of the Headrace tunnel – more than 6km of tunnelling.

Approximately 1,400 people are working on Snowy 2.0, with 150 local businesses involved and around 4,000 jobs are expected to be created during the life of the project.

Built by Future Generation – a joint venture between Webuild, Australian partner Clough and Lane Construction, a US subsidiary of Webuild – Snowy 2.0 will link the existing Talbingo Reservoir with Tantangara Reservoir through a network of tunnels.

Set in the Snowy Mountains, it will provide 2,000 megawatts of fast-start, dispatchable energy and provide 350,000 megawatt hours of large-scale storage, enough to power the equivalent of 500,000 homes for over a week during peak demand.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM