Read this article in Français Deutsch Italiano Português Español

Building inside mountains: Global demand for pumped hydroelectric storage soars

11 December 2023

Pumped hydroelectric storage plants around the world have been secretly storing electricity in remote mountain lakes for the last century. But the switch to renewable energy sources is prompting a surge in new construction. Lucy Barnard finds out more.

Looking out over the ragged beauty of the Scottish Highlands, Coire Glas, a horseshoe-shaped valley holding a clear mountain lake above the shores of Loch Lochy, seems like an unlikely spot to build a megaproject.

In this remote location, surrounded by clumps of pine trees, a team of construction workers from contractor Strabag are tunnelling their way through the rock which they hope will form part of a vast new power storage facility.

Work on the exploratory tunnel which measures 4m wide and will stretch for up to 1km into the Scottish mountainside, started in May 2023 and is expected to continue through most of 2024 as developer, power company SSE, firms up designs for a cavernous turbine hall deep in the mountain.

SSE says that its proposed pumped hydroelectric storage plant at Coire Glas, which will eventually comprise a 92m-high dam and two reservoirs, connected by a system of tunnels and a turbine hall, will more than double the UK’s ability to store electricity for long periods.

Cruachan Reservoir with Ben Cruachan behind. Photo: Adobe Stock

Cruachan Reservoir with Ben Cruachan behind. Photo: Adobe Stock

It says, the facility, which employs technology which has been in use for the best part of a century, to store the electricity generated by Scotland’s offshore wind turbines, could provide enough energy to power three million homes for up to 24 hours.

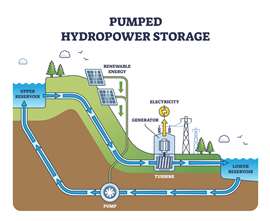

Certainly, the concept of Coire Glas is simple enough: A dam will be built across Coire Glas, forming an upper reservoir. During periods of low energy demand or surplus generation, electricity will be used to pump water from Loch Lochy to the reservoir 500m above, storing energy. Then, when demand is high, or other variable generation is low, the energy is released by using the water to generate hydroelectricity.

“Coire Glas is a classic example,” says Matt Sykes, a director at Arup responsible for running the civil structural and tunnelling teams, who has been involved in advising SSE at the project. “The project involves not just digging a tunnel through the mountain but also huge underground installations including a power cavern which is likely to be around 50m by 30m by another 30m. And then there’s all the cabling to get the electricity in and out. And there’s marine works. And all of this has to be done with the least possible impact on the environment so there’s quite a bit of work around that too.”

Although Scottish ministers approved the 1.5GW pumped storage facility in 2020, SSE says it is hoping that the UK government makes a commitment towards a revenue stabilization mechanism before it starts main construction work on the project.

“Engineering-wise Coire Glas is very challenging,” Sykes says. “Just getting access to the site, you’re looking at an hour in a specially modified vehicle. So any contractors are going to have to consider how to get machinery – possibly two or three tunnel boring machines – up there. It would be very expensive to haul lots of concrete to such a remote spot so building the dam is quite a challenge. And then, the site is on the Great Glen fault line so there are potentially some geological features that are going to be quite challenging because the fault has altered the rock.”

Why is building pumped storage so difficult?

Nicholas Burmeister, an engineer at Austria-based ILF Consulting Engineers, which is working on the Coire Glas project adds that even getting hold of the components for such a project can be a logistical headache.

“It really is a multi a multidisciplinary undertaking just getting the components,” Burmeister says. “The turbines and the pumps are huge. There are only a limited number of suppliers in the market. Placing an order with these guys is quite tricky. Trying to find time for them to do all the numerical modelling and then building physical models of the pumps and the turbines. Then they have to test them - they’ve only got a certain number of test beds, so they’ve obviously got limited production in their factories.”

“Even planning which port those pieces of equipment are going to come into or how they’re going to get to site can be a challenge,” he adds. “Making sure the seaport that the vessel is coming into has got the right cranes in order to lift the equipment. Do you have to construct roads or, do you have to reinforce any bridges on the way?”

Cruachan Power Station turbine hall. Photo: Drax

Cruachan Power Station turbine hall. Photo: Drax

Nonetheless, similar challenges have been faced and overcome before. Just a few miles away on the shores of the River Awe, the Cruachan Power Station, which works along the same lines, has been storing electricity in the Scottish mountains since 1965. During construction in the 1950s, a workforce of 1,300 men, known affectionately as the Tunnel Tigers, used handheld air drills to bore holes into the solid granite rock and then packed them with gelignite before detonating them.

Today Cruachan can provide 440MW of power and has become a tourist destination in its own right, complete with a highly rated tearoom. Dinorwig Power Station in Snowdonia national park in north Wales opened in 1984 can supply a maximum power of 1,728MW and has a storage capacity of around 9.1GWh.

In fact, the first pumped storage facility was opened in 1907 at Engeweiher in Switzerland and today pumped storage has become the most dominant form of energy storage around the world. According to the US Department of Energy Global Energy Storage Database, it accounts for 95% of all active tracked storage installations worldwide.

Burmeister says that in the past pumped storage facilities were built to balance the load placed on the electrical grid during periods of high demand – for example to cope with the surge in power caused when people across the country watch the same television programme at the same time and then switch on the kettle to make a cup of tea. However, since the advent of streaming services, this has become less of a concern.

Instead, as electricity generation moves from coal and gas-fired power stations to solar and wind, energy companies are once again investing in building new pumped storage projects to store power generated on extra windy and sunny days – and to use again on the days when the sun isn’t shining, or the wind doesn’t blow.

“It’s one thing to build loads and loads of offshore wind turbines. We see them spinning and we all think that’s powering someone’s kettle. But at the moment, most of that energy is not actually doing anything because the grid might have enough energy,” Burmeister says. “Pumped storage gives you that ability to store energy that would otherwise have been wasted.”

How hydropower storage works. Graphic: VectorMine via Adobe Stock

How hydropower storage works. Graphic: VectorMine via Adobe Stock

To that effect, after a lull of sometimes as much as 40 years, power companies around the world are rushing to build new pumped storage facilities.

Where will most new pumped storage facilities be built?

According to the International Energy Agency, global pumped storage capacity is set to expand by 56% to reach more than 270 GW by 2026, with the biggest growth in India and China.

Current pumped storage megaprojects currently in construction include the Kannagawa Hydropower Plant near Minamiaki in Japan which when fully completed in 2032 is expected to have a total installed capacity of 2,820MW; and Snowy Hydro 2.0 in New South Wales, Australia, which is currently expected to complete in 2028.

Sykes says that the surge in demand for pumped storage is the main reason why ILF has signed an MOU with Arup to work on Coire Glas and up to 13 other similar projects. And, as renewable energy sources provide an increasing supply of global power, demand for such mega projects is likely to grow even further.

“New pumped storage schemes such as Coire Glas are crucial for net zero,” Sykes says. “At the moment, all around the world, we’re paying a lot of money to have our wind turbines turned off when it’s windy because once the wind exceeds demand then you’ve got no way of storing that energy. The beauty of pumped storage is that it’s a century old technology that allows us to store that energy cleanly for the times when we do need it. We won’t be able to achieve net zero without it.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM