Cool running: why temperature is key for equipment manufacturers

Partner Content produced by KHL Content Studio

11 August 2025

In construction and other heavy equipment industries, the age-old buzzword of efficiency is increasingly joined by automation and sustainability.

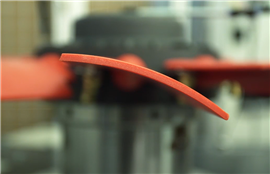

Reversible fan blades are a powerful cleaning tool for machines working in areas with high levels of particulate matter

Reversible fan blades are a powerful cleaning tool for machines working in areas with high levels of particulate matter

It’s fair to say that cooling systems are unlikely to be at the top of the agenda for original equipment manufacturers (OEMs).

Yet cooling plays a critical role in machine performance, reliability, and maintenance. Advances in fan technology should be of increasing interest to manufacturers looking to give customers a greater return on their investment.

The automatic expelling of particulate matter from radiators is one of the highly beneficial aspects of machine automation

The automatic expelling of particulate matter from radiators is one of the highly beneficial aspects of machine automation

With further emissions regulations seemingly on hold, OEMs have an opportunity to turn their focus back to core machine functionality. Innovations such as self-cleaning fans could be central to improving performance, uptime and efficiency.

Automation and cooling

The push toward autonomy – which today largely means function-specific automation – is already enhancing machine performance in construction. This will become increasingly important, as experienced operators retire or leave the industry.

Mark MacDonald, Sales Manager with Cleanfix Fans, which produces reversible fans for heavy equipment across a range of industries, says, “On average, I think the automation of machine functions is increasing productivity, and that can be significant for businesses running heavy fleets.”

Some level of autonomy is clearly beneficial, but fully autonomous vehicles introduce new challenges, particularly when it comes to maintenance. For example, without an operator present to address issues on the fly, a simple clogged radiator can escalate into critical time lost due to overheating or insufficient air flow.

At the push of a button, an operator can reverse the fan blades, to eject dust and other particles from the radiator

At the push of a button, an operator can reverse the fan blades, to eject dust and other particles from the radiator

“An issue that would have taken an operator a few minutes to address might now turn into hours, if you have to wait for someone to physically go to the site,” MacDonald explains.

This potential shift in machine maintenance means preventive solutions, like automatic cooling system cleaning, will have even greater value.

Cooling: a design challenge

“For OEMs, trying to package cooling systems has been a challenge, probably since the Tier 2 emission regulations came into force,” says MacDonald.

“Frankly, it’s easy enough to specify a fan that can provide the required airflow. Now, it’s more about fitting the system into a space-constrained, cost-sensitive machine architecture.”

Add to that the need to maintain operator visibility, ensure servicing can be easily undertaken and minimize weight and complexity, and the importance of smarter fan design is clear.

“Clean coolers are more efficient. No argument there,” says Shayne Rose, Cleanfix’s Engineering Manager “Introducing a regular cleaning cycle improves the overall efficiency of the cooling system. It decreases the fan’s power requirement and boosts machine performance.”

The powerful self-cleaning fan can eject leaves and other matter from heavy equipment

The powerful self-cleaning fan can eject leaves and other matter from heavy equipment

This combined with technologies like variable blade pitch enhances the fan’s benefits, as cleaner systems require less airflow. The fan does not need to work as hard, which saves energy and potentially extends the life of the machine’s components.

Self-cleaning fans

Traditional hydraulically-driven reversible fans work by slowing and reversing fan rotation to blow debris out of the cooling cores.

While this approach was once state of the art, it does come with compromises.

“Reversing the fan takes time,” says Rose, “during which cooling performance drops, and that’s a potential issue in high-load, high-temperature conditions.

“You can’t regain the cooling performance, as the fan is now spinning backwards, and you can’t clean as effectively.”

The drag effect of reversing a fan’s rotation is wasted power – which is lost to the machine, even when the engine is not demanding a high degree of cooling. So, what can be done about this parasitic loss?

Mark MacDonald

Mark MacDonald

Cleanfix fans take a fundamentally different approach. Rather than reversing the fan’s direction, the blades themselves pivot, reversing the airflow. “In this way,” he says, “the fan is able to maintain a high level of cooling efficiency and also provide high-quality cleaning performance.”

It’s an elegant engineering solution to a real-world performance challenge.

There’s a clear sustainability angle to self-cleaning fans, too. “Whether that be in terms of the capital cost or sustainability from the increased lifespan of the machine, a state-of-the-art fan is going to improve both,” says MacDonald.

“Regular cleaning of the radiator minimizes thermal stress on the engine, lowers the risk of overheating and reduces the likelihood of catastrophic failures – all of which extend the life of major components and reduce downtime.”

A better-performing engine will also consume less fuel.

Fan blades are rotated through the fan hub on their own axes, allowing them to be rotated into the best position for cooling and cleaning

Fan blades are rotated through the fan hub on their own axes, allowing them to be rotated into the best position for cooling and cleaning

For OEMs with sustainability goals – or end users aiming to get more from their fleet with minimal downtime – this is a win-win.

Self-cleaning fans would seem a good fit for environments such as quarrying and agriculture, in which debris is a constant concern. In these sectors, daily radiator cleaning is more or less the norm.

“You don’t want to have to manually clean out the radiators once a day. It’s not a fun job and nobody likes doing it,” MacDonald says. “If you can get to the end of the day and press a button and that’s the radiator clean, then who wouldn’t want that?”

But the benefits aren’t limited to extreme use cases. In more moderate environments, where the build-up of dust doesn’t always trigger warning lights or immediate issues, machines operating at less than 100% efficiency can often go unnoticed.

“From a fuel efficiency perspective, it’s difficult for end users to quantify the losses in the performance of their machines,” says Rose. In these cases, self-cleaning fans could offer a proactive solution to reduce those accumulating issues.

Graphic shows the simple process by which timed reversals of the fan blades’ pitch can be achieved

Graphic shows the simple process by which timed reversals of the fan blades’ pitch can be achieved

Rose says technology has hugely benefited the process of manufacturing the Cleanfix unit, helping to minimize its mass to ensure maximum fuel efficiency, while pointing to robust materials that give it impressive strength and durability.

Smart integration

According to MacDonald, OEMs will gain most value by engaging early with fan design teams. “That might mean some rethinking of the other systems,” he says, “but the goal is to bring value and benefit to the OEM.”

In terms of the technology built into the fan systems, he says they offer multiple control options and can be triggered via timer, machine logic, or manually by the operator. “On the cooling side, the system uses a closed-loop electronic control system to vary blade pitch based on real-time temperature data.

Cleanfix Engineering Manager, Shayne Rose

Cleanfix Engineering Manager, Shayne Rose

This control can be integrated into the OEM’s ECU or by use of a control module which controls blade pitch via data from the vehicle CAN bus.

That level of integration allows the fan to dynamically adjust to changing cooling demands, further enhancing efficiency.

MacDonald also describes a unique alternative to electronic pitch control – the Cleanfix Variable-Pitch system.

This uses fan mounted thermal cells to mechanically pivot the blade to the required angle based on cooling air temperature. The solution eliminates all extra programming, hardware and sensor requirements.

Competitive advantage

Self-cleaning fans are now less a niche add-on and more a practical, performance-enhancing component that addresses growing industry challenges, such as labor shortages, machine uptime, sustainability, and total cost of machine ownership.

For OEMs, integrating self-cleaning fan technology is a way of differentiating their machines and at the same time reducing costs for end users.

“In the end,” says MacDonald, “it works for everybody.”

--------

This article was produced by KHL’s Content Studio, in collaboration with experts from Cleanfix North America

--------

All images courtesy of Cleanfix North America

--------

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM