ConTech: Not a silver bullet, but a long-term partner

12 August 2022

KHL’s Construction Technology division recently undertook a survey, aiming to take the temperature among contractors of the digital transformation of the industry and construction technology in general.

The response confirmed that construction is waking up to the need to adopt digital technology, but also that there is, in many cases, a reluctance to put significant resources into technology, before being convinced of the return on investment.

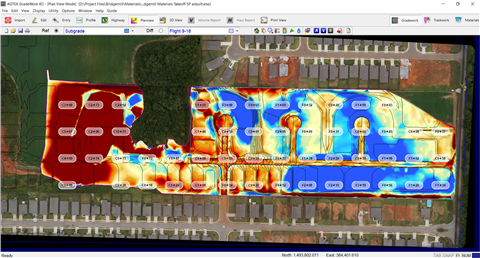

Use technology from the outset, to get a deep understanding of what a project entails. Image: Hexagon

Use technology from the outset, to get a deep understanding of what a project entails. Image: Hexagon

Construction Europe went to Matt Desmond, President Agtek, Vice President Heavy Construction, Construction Management Solution at Hexagon’s Geosystems division, for his take on things.

How are you seeing construction businesses changing, when it comes to adopting technology?

We have seen a change in attitude in general to digitalisation, both during Covid and post-Covid.

Largely we see two main camps of the way people are digitising their construction sites.

One is a more incremental approach, where companies are looking at one problem area of their organisation and focusing on that area.

That might be in a particular department or one particular job function – maybe focusing on the bidding side, the finance side or the operations side – and they may implement a particular technology to solve that problem, whether it be grade control, machine control or take-off and estimating software. But generally, it’s one problem at a time and they try and find the greatest problem.

The other area of implementation is transformational change, where a company looks to change a whole lot of things at once, to improve cross-divisional issues.

I think we saw, at the start of Covid, more systems thinking about the whole data-flow chain, and a lot of that was driven by the need for remote communication and the need to do things differently.

So, post-Covid, we still have these two approaches, but I wouldn’t say one is right and one is wrong.

I think the best approach is to start the digitisation, where it’s appropriate for the company you’re in – and if you’ve got champions and sponsors within an incremental approach and an individual problem you’re trying to solve, that’s a great place to start.

Given there is a need for construction businesses to make the change – be it piecemeal or wholesale – what can tech companies do to make the transformation easier?

I see the training and the empowerment of the organisation as very important, but I wouldn’t necessarily say that’s the realm of the larger contractor. I’d say what’s important is to have a champion who’s going to really push the change through the organisation.

Quite often, that’s more easily done in a smaller company, where departments and people are closer together and the drive can come from a more senior leader.

Sometimes, these transformational changes are pushed from the top in larger organisations, but they’re lost through the implementation process.

What really is important is education and being able to utilise the technology.

Making the decision to adopt digital technology does not have to mean spending millions. Photo: Hexagon

Making the decision to adopt digital technology does not have to mean spending millions. Photo: Hexagon

We play a huge part in that process. We know the technology better than the company implementing it, but the company implementing the tech knows its processes and issues, so the two need to come together along with the people using it.

Is it fair to say that some of the technology being developed for the construction industry is too complex to be properly utilised by non-experts?

When companies adopt a technology, they often see it as a silver bullet – that the technology itself is going to change everything about the organisation and work without putting in the time.

You typically don’t get really good at something without learning about it in some formal manner.

People don’t necessarily see that with technology. They buy technology and expect it to work without putting in the time to learn and work with it.

The need for changing processes and understanding where it fits into your organisation is really important.

Also, fully understanding the problem you’re trying to solve with the technology is important.

I stress that for technology adoption, technology is only one part; I’d really look at people, processes and technology. All three of them feed into making a successful implementation.

So, it’s a long-term partnership between the technology provider and the customer?

One hundred percent. We don’t sell technology, we sell a solution to a problem – and that solution can come in many forms.

Technology is the medium that enables the problem to be solved, but we need to look at it as a whole system that has inputs and outputs – and the technology provider is not in control of all of them.

Do you think there’s a need for governments to incentivise change in the industry, to help make it more sustainable?

There’s certainly a resistance to change, and a lot of that comes from contractors being too busy.

I’d say that many contractors don’t fundamentally believe there’s a need to change.

And the main barrier is time, as well as finding skilled labour and finding enough resources you need to find time to allow for something different to be done.

The easy thing is to wake up and do what you did yesterday; it’s a harder thing to do something different.

Matt Desmond, VP at Hexagon’s Heavy Construction division

Matt Desmond, VP at Hexagon’s Heavy Construction division

So, I think change is difficult and not necessarily being pulled at the rate that it could be from industry.

Change comes from creating value out of technology, and most of the technology is designed to complete projects faster, more profitably, to higher specifications and more safely.

As a technology provider, if we can solve those problems, contractors make more money, so I think, fundamentally, adoption comes down to natural market forces.

We need to make construction companies more profitable; if we do, they’re going to adopt more technology.

If they can build to specification better, they’ll use less material, they can do things faster, they’re going to burn less fuel and reduce CO2 emissions.

So, I see adopting technology as a virtuous cycle that fulfils all those needs, but the main driver is making construction companies more profitable.

The benefit of not winning jobs

One area of this that’s often overlooked is not just the job that you win; technology can help you to not win, a non-profitable project.

Making sure you understand all the lengths, areas, counts and volumes of material before you bid a job, can be equally important to winning a job and not understanding those details.

Because if you win the wrong job, it’s going to be painfully unprofitable, no matter what technology you throw at it.

So, in that technology adoption phase, I’d also add bring technology early in the workflow of a construction company; really understanding what you’re going to build, rather than simply trying to measure what you are building.

Data security is one area of digitalisation that is proving a concern for some construction businesses. Are they right to worry?

In general, construction is a laggard in implementing technology, so a lot of the problems of data security have been solved many times over by other industries.

In terms of mixed fleets, Hexagon’s philosophy is to provide technology that’s easy to use and easy to adopt using open standard platforms and formats. Thus, part of that easy-to-adopt concept is working with systems that may already be in place.

We have a role to play, both in solving data security issues and providing the best possible solutions, so customers continue their digitisation journey with us.

Do you have an example of some digital technology the looks most exciting for today’s industry?

One of the adopting technologies we’re seeing is UAVs/ drones and reality capture technology to create a digital twin.

Understanding what’s being constructed at the start, what are the existing conditions like, then tracking the process throughout the construction process, to make sure you’re measuring against that initial scorecard that you’ve created is, I would say, one of the single biggest revolutions we’ve seen in the market.

UAVs are becoming very accessible to construction companies; they’re relatively cheap, they work effectively and, with the right working methods, can be extremely valuable.

I think soon, the standard kit inside a foreman’s vehicle will include a drone – and utilising the data that comes out of that drone is where the benefit lies.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM