Read this article in French German Italian Portuguese Spanish

Flying construction robots complete first real-world tests

24 April 2025

New research led by Imperial College London, with contributions from the University of Bristol, has revealed that aerial robotics could enhance safety, sustainability, and scalability in the construction industry.

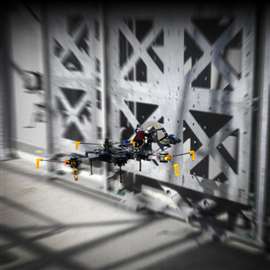

Experiments with flying construction robots on the test wall of the DroneHub with modular components (Photo: Yusuf Furkan Kaya)

Experiments with flying construction robots on the test wall of the DroneHub with modular components (Photo: Yusuf Furkan Kaya)

The study focuses on the use of drones for mid-air material deposition, a process known as Aerial Additive Manufacturing (Aerial AM).

The approach aims to tackle global housing and infrastructure challenges by utilising aerial robots equipped with advanced manipulators. The robots are said to overcome the limitations of traditional construction methods and ground-based robotic systems.

The innovations presented in the research are said to improve productivity and environmental sustainability while providing access to elevated heights, hard-to-reach areas, or hazardous locations, all while minimising waste and energy consumption.

Unlike conventional construction techniques and ground-based robotic systems, aerial robots operate in an unrestricted work envelope. This capability allows them to construct in greater heights and challenging terrains that are otherwise inaccessible.

Dr Basaran Bahadir Kocer, co-author from the University of Bristol’s School of Civil, Aerospace and Design Engineering, said, “Despite promising advancements, the deployment of aerial robots for large-scale autonomous construction remains in its infancy. Key obstacles include material durability, localisation systems for outdoor environments, and coordination among multiple aerial units.

“Addressing these challenges is essential to unlocking the full potential of Aerial AM in real-world applications. However, early-stage demonstrations of Ariel AM have already showcased capabilities such as rapid on-demand repairs and modular assembly techniques, paving the way for broader adoption across industries.”

The new technology is currently being tested at the DroneHub, which is based in Switzerland at EMPA – the Swiss Federal Laboratories for Materials, Science and Technology, which provides a platform on which flying construction machines can be tested outside the laboratory for the first time.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM