Bechtel appointed to advise on proposed Tennessee SMR

24 January 2025

The Tennessee Valley Authority (TVA) has appointed US-based engineering multinational Bechtel to help plan and design a small modular reactor (SMR) at its Clinch River Nuclear site in Tennessee.

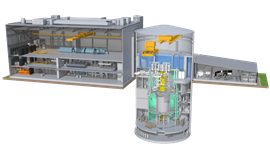

GE Hitachi’s BWRX SMR. Image: GE Hitachi

GE Hitachi’s BWRX SMR. Image: GE Hitachi

The USA’s largest public power provider said that it had also appointed Chicago-based power and energy engineering specialist Sargent & Lundy and GE Hitachi (GEH) to work on the early-stage project to install a BWRX-300 SMR.

TVA said that, unlike previous nuclear construction projects in the USA, the contractors will work together using an integrated project delivery (IPD) approach to plan, design and potentially procure, construct and commission the 300-megawatt project on a 935-acre site.

It said that the partners were currently in the project’s validation phase where, over a period of 1-2 years, they will collaborate to jointly develop a cost estimate and schedule for the project. In future they intend to enter into a multi-party agreement under which incentives and arrangements will be negotiated to help ensure those estimates are achieved.

Even though TVA hold’s the USA’s first (and currently, only) early site permit for SMRs at Clinch River, the company said its board had not yet voted to approve an SMR at the nuclear site.

Last year Bechtel broke ground on an SMR project in Wyoming for TerraPower, an energy company owned by Bill Gates.

Dozens of companies are currently vying to develop a new generation of SMRs which proponents say could be the best way to resolve the climate crisis, producing plentiful carbon-free power in buildings the size of a few soccer pitches which could be hitched up to anything from towns to data centres using established technology which has been employed for decades in submarines and icebreakers.

However, so far, outside of state-controlled nations such as Russia and China, no country has found a way to build a commercially viable SMR.

“We must push these technologies down the cost curve by building more units,” said Craig Albert, president and chief operating operator of Bechtel in a blog post. “as with any new technology, once standardisation and repetition are achieved, construction schedules shorten, and costs go down. Over time economies of scale are realised. This is true in every aspect of project delivery including engineering design, permitting, manufacturing and construction.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM