What is HVO and why is it important?

06 September 2021

Ahead of his appearance at Futureworx 2022, William Tebbit, the CEO of fuel specialist and GreenD+ manufacuturer Green Biofuels, exmaines what HVO is and how its use is decarbonising the UK construction industry.

Much of the public debate and Government policies around the road to Net Zero, decarbonising the UK and improving air quality, is about what we are going to do.

What our intentions are and how new technologies are going to achieve amazing things in 2050, or is it 2040 or 2030? However, the harsh reality is about today not tomorrow.

William Tebbit, CEO at Green Biofuels

William Tebbit, CEO at Green Biofuels

Today our air quality is so poor the UK continues to be fined and today we are still a long way from Net Zero whenever that maybe.

The promised technologies whilst becoming available are both expensive and not available in sufficient volumes to make a real difference today.

It is too easy for governments to make grand plans for the future safe in the knowledge they won’t be around to be judged on the success or failure of those grand plans.

As with many commitments made by governments, it falls to the commercial world and the taxpayers (who fund it all!) to actually make it happen.

But on the back of Covid and with record borrowing, delivering on the net-zero target now looks like a rather more daunting task. This is no doubt why so much attention is focused on other types of low carbon fuel sources.

Many others I am sure will discuss CNG, Hydrogen, EV and Biogases however, I want to shed light on what is available today and is making a difference today.

What is Hydrotreated Vegetable Oil (HVO)?

Principally I want to reveal the best kept secret in advanced fuels which is paraffinic diesels made to EN15940 standard and in particular GreenD+ which Green Biofuels supplies in the UK and increasingly into Europe.

GreenD+ isn’t biodiesel; it’s a bioliquid that can be used at 100% in any diesel engine. We have achieved a pretty much universal OEM approval for GreenD+ which is a Hydrotreated Vegetable Oil or often referred to as HVO.

Make no mistake this is the simplest and easiest way any operator of any diesel engine can immediately improve air quality and reduce Green House Gases. It is a total drop in fuel. There are no alterations required to engines or storage or delivery. ...So how good is it?

The environmental benefits of HVO

-

HVO is a waste derived fuel and so qualifies as a renewable and sustainable fuel

-

It reduces NOx by up to 29% over regular diesel

-

It reduces particulates by up to 85%

-

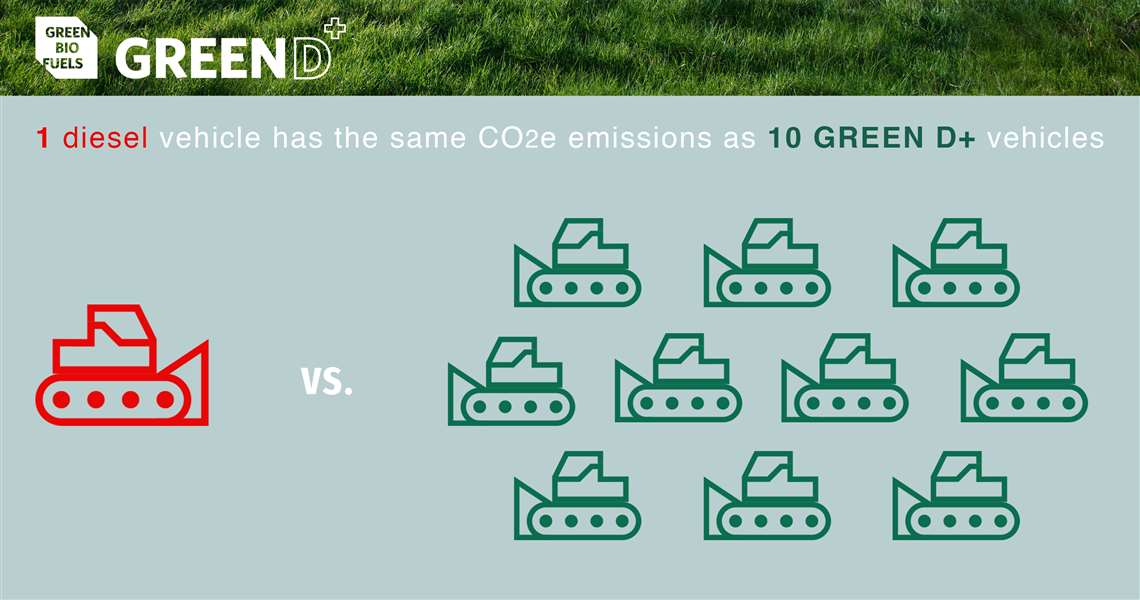

It reduces carbon dioxide equivalents (CO2e) by up to 90%

-

It can be used in any diesel engine

What are the disadvantages of biofuels?

So, what is the draw back? It is more expensive than regular diesel; typically, 8-10ppl but the benefits of improved air quality for both the public and for site workers is immediate. The CO2e reduction is very significant; up to 90%.

By way of illustration, the carbon intensity of HVO is 34g CO2e per kwhr and electricity from the National Grid in the best month on record in May 2020 was 143g CO2e and the lowest day on record was 46g CO2e; we believe this fact should be taken into account when considering GreenD+ as a transition technology.

So, what is GreenD+ best for? It is, in my opinion, the best transition technology available for large diesel engines; and it is available today throughout the UK.

Switching improves local air quality and helps with the health and wellbeing of all those on sites. Smart tanks allow you to monitor and control fuel on site and make further environmental savings through optimising logistics and capturing data.

A large number of operators are now using GreenD+ including large commercial fleets of HGV’s such as Hovis, Large Logistic Operators, Construction companies such as Skanska, Volker Fitzpatrick and Sisk & Co, Marine operators such as GPS Marine on the Thames and the list continues to grow.

How HVO lowers carbon emissions from equipment manufacturing

Perhaps for me the most compelling carbon reduction argument for using advanced fuels like GreenD+ is that it is used in existing plant and equipment without the daunting capex cost of new plant and we reduce the carbon emissions of producing new equipment in this transition phase.

It goes without saying if you’re using regular diesel and there are alternatives available today that improve air quality and reduce CO2e as GreenD+ does the tougher question to answer is why aren’t you changing rather than why should I change? We clean the air today and reduce CO2e today.

We are not waiting for 2050 or 2040 or 2030. In the last 12 months our clients have reduced CO2e by 67,000 Mt.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM