Sustainable road construction focus for Wirtgen at ConExpo

07 February 2023

Wirtgen will focus on sustainability at ConExpo

Wirtgen will focus on sustainability at ConExpo

Wirtgen will present a cross-section of its cold milling, recycling, soil stabilising and concrete paving products on the joint booth shared by Wirtgen Group and John Deere.

Alongside nine exhibits from three product sectors, the focus will also be on digital system solutions and assistance systems.

Among the equipment on display will be the W 50 Ri, Wirtgen’s powerful half-metre cold milling machine with rear loading. Its features include a simple operating concept and automatic functions. The W 120 Fi front loader has been designed for working widths of up to 1.3 m (4ft 3in).

The F-Series compact milling machine is fitted with a John Deere engine that has been customised to meet the special demands of cold milling applications. Two large F-Series milling machines complete the cold milling machine range on show.

Cold recycling and soil stabilising equipment will also be on show, such as the W 380 CRi as well as the WR 200 XLi and WR 250i. The W 380 CRi with rear loading and a mixing performance of up to 800 t/h is used for rehabilitating wide roads. It can be deployed in both cold in-place recycling (CIR) and in full-depth reclaiming (FDR) projects.

Wirtgen and John Deere will share a stand at ConExpo

Wirtgen and John Deere will share a stand at ConExpo

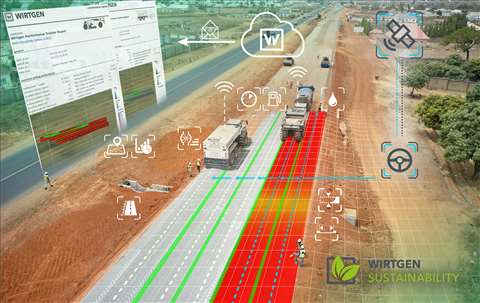

Besides cold recycling, the WR-Series wheel-driven recyclers can also carry out soil stabilising tasks. With a working width of 2.4 m (7 ft 10 in) as well as high milling and mixing performances, they are well-equipped for use in demanding projects with high daily outputs. The digital system solutions, the AutoTrac steering system and the WPT (Wirtgen Performance Tracker) documentation system further increase process efficiency.

At ConExpo Wirtgen will show the SP 15i and SP 94i, two customisable concrete paving machines. The SP 15i allows flexible slipform paver positioning, said to be a huge advantage when producing monolithic profiles in an offset process. The machine also has a telescopic operating platform extension for a better view of the working area and the paving result.

Furthermore, the machine can be controlled without a stringline using the specially developed AutoPilot 2.0 control system. The SP 94i is a fully modular inset slipform paver in the 30 ft class. A 4-crawler paver with the TeleMold system will be presented in Las Vegas.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM