Siemens Energy to supply equipment for gas storage

22 April 2021

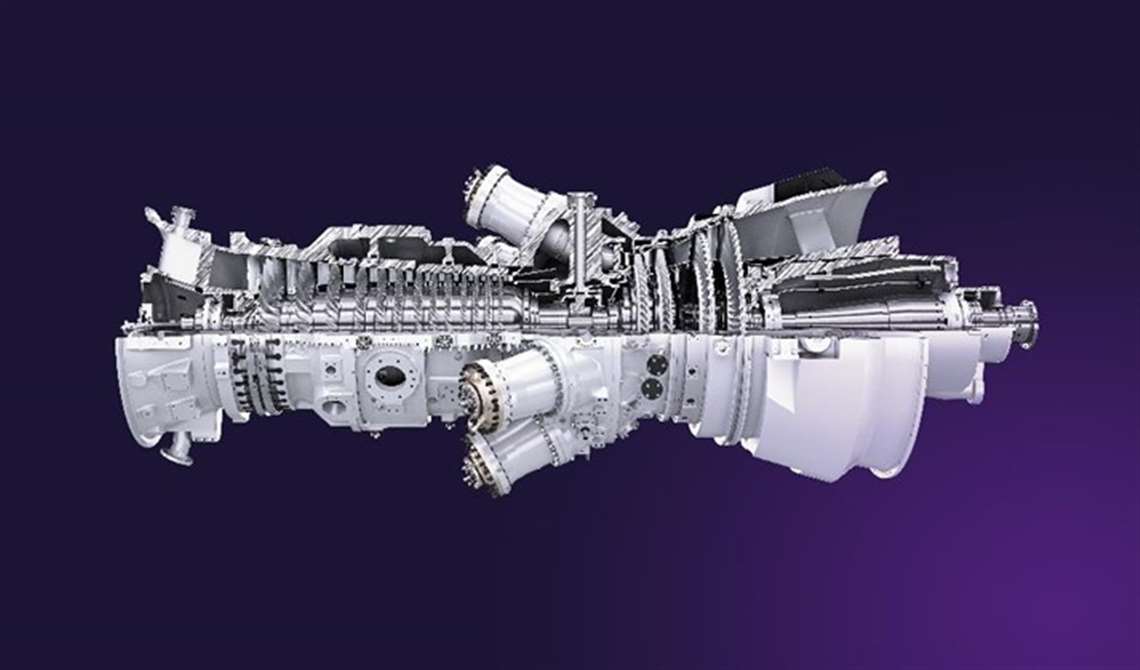

Uzbekistan project includes two compression trains driven by SGT-750 industry gas turbines

Siemens Energy was chosen to supply two low-emission compression trains for Phase 1 of the Gazli Underground Gas Storage (UGS) project in the Bukhara region of Uzbekistan.

The two trains will help extract up to 20 million standard cubic meters per day (MMSm3/d) of stored gas in the Gazli field and pressurize it for transportation by pipeline to domestic users in Uzbekistan and export to China.

Each train will feature an efficient, single-casing DATUM centrifugal compressor directly driven by an SGT-750 industrial gas turbine (41 MW IS), Siemens Energy said in a prepared release. The project is the first application of the SGT-750 turbine in Uzbekistan.

The SGT-750 turbine’s DLE combustion system offers excellent emission performance and fuel flexibility over a broad load range, the company said. The turbine can achieve single-digit NOx emission levels down to a 20% load and does not require a speed-increasing gearbox.

Waste heat recovery units will be installed on both trains to capture thermal energy from the turbine’s exhaust and supply hot water for onsite heating.

“The Gazli Underground Gas Storage project is of strategic importance to Uzbekistan and will play a critical role in sustainably meeting the country’s domestic energy demand,” said Thorbjoern Fors, Executive Vice President for Siemens Energy Industrial Applications. “Our in-country presence and ability to provide maintenance and support to the equipment using local content were also integral to this key project win.”

“In addition to its low emissions profile, the EPC selected the SGT-750 gas turbine based on its shaft power and high availability,” said Arja Talakar, Senior Vice President, Industrial Applications Products for Siemens Energy. “This will allow the end-user to meet full flow requirements in both the summer and winter months with just two compression trains when three would normally be required.”

Under terms of the agreement, Siemens Energy will provide financing for 90% of the contract’s value. The turbines will be manufactured in Finspong, Sweden. The compressors will be manufactured in Le Havre, France. The trains are scheduled to be commissioned in late 2021, Siemens said.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM