Read this article in Français Deutsch Italiano Português Español

How hard should construction robots be allowed to hit human workers?

25 November 2024

The study says there is an ‘urgent’ need for safety guidelines for robots on open construction sites (Image generated with AI via Ideogram)

The study says there is an ‘urgent’ need for safety guidelines for robots on open construction sites (Image generated with AI via Ideogram)

If construction robots aren’t able to detect their human worker counterparts on a site accurately enough, then it’s important to know how hard they can bump into them without causing harm.

That was the starting point for a new study that aims to improve safety for human workers as robots and co-bots become a more common sight on construction jobsites for all sorts of tasks including bricklaying, road paving, drywall installation, and demolition.

The US study was conducted by researchers from the Division of Safety Research at the National Institute for Occupational Safety and Health (NIOSH), Department of Civil Engineering, Stony Brook University, USA, and PILZ Automation Safety.

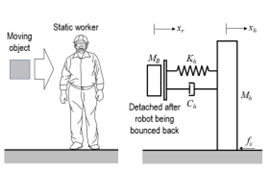

Mechanical model of the side impact between the static worker and the moving robot. (Source: Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites)

Mechanical model of the side impact between the static worker and the moving robot. (Source: Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites)

It warned that robots and co-bots have the potential to injure workers by unexpected contact and that they therefore need to be operated under specific safety procedures to prevent harm.

The researchers noted that modern robots have tools that can help them to detect their human counterparts, including computer vision devices that can sense the movement of workers around them and allow them to work out how to avoid them.

But they added that the technologies are not currently well adopted to construction activities, where environments are less structured, and manipulation tasks are complex.

“An open jobsite such as a construction site is often not an ideal environment for robots to have all necessary sensors to detect workers’ movements and environmental changes,” they said.

“Environmental disturbance, noises, and an insufficient number of sensors can greatly affect the ability of the robot to detect surrounding hazards and movements of existing objects in the construction space.”

Construction sites make continuous tracking of workers hard

That means while robots may be able to detect the presence of workers, they might not be able to monitor them continuously from all directions on an open jobsite. And if they can’t recognise the worker’s movements, that means it is less likely that the robot can perform all the required safety operations based on the worker’s body posture.

So if you can’t rely on robots avoiding workers in a construction setting, then a different approach is needed. The researchers said that this involves “regulating energy transfer between the human worker and the robot, or the construction material carried by the robot” – in other words, working out how hard robots can bump into humans without causing them injury.

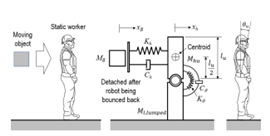

Mechanical model of the back impact between the static worker and the moving robot. (Source: Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites)

Mechanical model of the back impact between the static worker and the moving robot. (Source: Safe Operations of Construction Robots on Human-Robot Collaborative Construction Sites)

The study considered two cases of robots carrying masonry blocks making an unexpected impact with workers: The first where the worker is struck and forcibly pushed away from their original position (‘struck and pushed’); and the second where the robot contacts the worker from behind and their upper body bends forward around the waist while their lower body remains unmoved (‘struck and bent’).

Researchers developed a set of complicated mathematical equations to model the impacts between a male human construction work and robotic devices on a dry construction site in each scenario.

The simulated results showed that the payload of the robot would need to move at slower speeds in the ‘struck and bent’ scenario to avoid greater contact force than in the case of ‘struck and pushed’.

The study found that the maximum speed of a masonry robot should be less than 700 millimetres per second if the robot is carrying a 17-kilogram block, and 570 millimetres per second if it is carrying a 25-kilogram block.

If it travels at that speed then the potential from injury can be “adequately prevented”, it found.

Safety guidelines needed

It concluded, “This approach can provide reference values for safely operating robots on construction sites. In the future, dynamic models for different scenarios and different operational environments could be developed, such as rainy weather and muddy ground.”

Those reference values could be used to inform future safety standards. Currently, while safety standards for collaborative and mobile robots in the manufacturing industry have been produced, no such standards have not yet been developed in construction.

“If safety regulations do not clearly dictate a specific operation, workpieces carried by existing robots could strike human workers while operating in an open environment,” the study said.

“The construction industry urgently needs safety guidelines for the use of robotic equipment on open construction sites.”

NIOSH’s paper was presented at the 41st International Symposium on Automation and Robotics in Construction (ISARC) in Lille, France, earlier this year. To read the full paper, click here.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM