Paraguay’s 1st TIP Project

03 November 2025

Sponsored Content

Construction of Paseo 55 marked a momentous occasion for foundation testing; Pile Dynamics’ Thermal Integrity Profiler (TIP™) was utilized on a 55-story, 212-meter-high apartment building that would redefine the city skyline. As the largest residential tower in Paraguay, Paseo 55 will become an architectural landmark for Asunción.

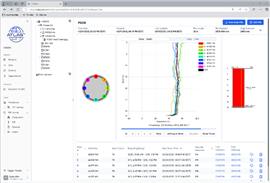

The project plans included barrette piles that ranged from 36-40 meters in length. 50% (22 of the 44) barrettes were tested for concrete integrity with the Thermal Integrity Profiler (TIP).

The challenge of this project involved the installation process prior to testing. Due to the confined space of the construction site, barrettes were used for easier access. To minimize risk of Thermal Wire® cable damage after instrumentation, PVC piping housed each cable installed and extended above the top of the pile’s reinforcement cage for access.

Pile Dynamics sent an experienced engineer to the project site for hands on demonstration/instruction with field personnel on proper installation methods, and to help troubleshoot any issues presented in real time. Great importance was placed on the installation method of the Thermal Wire cables. Each barrette utilized 8 wires that ran the full length of the shaft, with the barrettes installed below grade.

It was extremely important to install the thermal wires properly, considering the bending of the cages during lifting operations. Due to the length of the barrettes, cages were spliced together requiring pre-planned splice sections of Thermal Wire cable to assess integrity over the entire length of the reinforcement cage. The Thermal Wire splice provided a simple, quick and safe alternative when compared with splicing CSL tubes.

All the barrettes were installed below grade and gravel was placed on top to fill the void from the top of concrete to grade. To minimize damage to the Thermal Wire cables, PVC tubes encompassed each cable to protect the wires during placement of the gravel. Thermal Integrity Profiling often uses thermal measurements to determine a drilled shaft’s effective radius. Due to the shape of the barrettes, the temperature measurements alone were able to provide a qualitative analysis of the concrete quality, since effective radius was not able to be calculated.

Corner wires behaved similarly with heat dispersion and wires along the sides of the barrettes were evaluated for consistent readings.

Temperature results were assessed throughout the entire hydration process to identify any cage alignment shifts and any localized reduction in temperature was potentially an indication of an inclusion or poor-quality concrete.

TIP results indicated slightly cooler temperatures at the barrette corners, which was anticipated. In general, results indicated minor cage alignment shifts which were not cause for concern. No local anomalies were identified through temperature measurements. Due to the efficiency of TIP testing, analysis of the data was possible within 3 days as peak temperature was achieved, allowing acceptance and subsequent work to proceed. Within 30-40 hours, results were available for assessing the concrete integrity, identifying potential anomalies or bulges, and provided time to address any issues that may have occurred.

Pile Dynamics, Inc. is the industry leading manufacturer of quality assurance products for the Deep Foundations Industry. They are located in Cleveland, Ohio, USA, and has commercial representatives in all continents. For more information visit www.pile.com/pdi.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM