The sky’s the limit: the latest in drone technology

10 March 2023

Drones are increasingly accepted as part of the construction process and their applications for the sector are ever evolving, discovers Andy Brown.

Drones, also known as unmanned aerial vehicles (UAVs), have been around in the construction industry for a number of years, but it is only in more recent times that their use has become more accepted and their benefits almost universally understood.

Part of this is the common cycle of anything new – it takes time to figure out the best way of utilising a new tool. Jim Greenberg, product manager in the Trimble Civil Engineering division remembers that “In 2018 there was a lot of hype around drones. We were all trying to get our heads around what it really was and what it really meant… There were a lot of things to figure out, and surveyors were getting up to speed with it.”

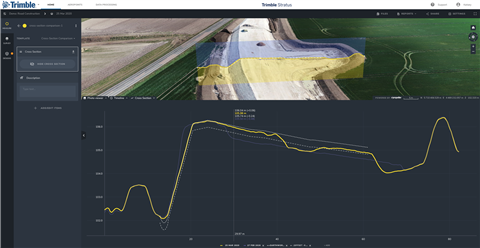

Finding someone to fly the drone could be an issue, but it wasn’t the biggest one – that was collecting data (and the right data) and then knowing what to do with it, and what it meant. These kinks have now been ironed out to the point that Greenberg, who is a surveyor by trade, says, “now I feel like it’s just a given; like GPS and machine control, people don’t question if it is good anymore.

“They just question how they can apply it. We feel that it’s at the point where it’s accepted and everyone’s starting to look at it. When you put it in someone’s hands, they figure out the added value they can get from it. We have companies that say this is as transformational as machine control was.”

The evolution of drone technology

This viewpoint is backed up by Pascal Martinez, director of OEM Development at Bentley Systems. When asked if drones are more accepted in construction now, he answers emphatically, “Yes. Drones have evolved incredibly over the last ten years and, with prices down and increased ease of use, they are becoming a key tool to monitor construction progress.

Pascal Martinez director, OEM Development at Bentley Systems

Pascal Martinez director, OEM Development at Bentley Systems

“Of course, they are mostly used in horizontal construction and the structural work on vertical construction, but there are new drones that can also fly indoors. And their utilisation can be combined with 3D laser scanning to create a complete reality model of a construction site. A key driver of this adoption is also the autonomy, it relieves the need for an expert pilot and enables repeat flights and acquisition at high pace.”

As the technology has developed so has the speed at that data can be processed – data can be uploaded to the cloud and available shortly after for evaluation thanks to the readily available processing power. Some contractors are even flying multiple flights in one day and uploading them simultaneously.

The increasing automation of drones is playing a role in their adoption, as is the fact that the way they

are being used has also evolved. Initially, drones were used across construction to get to locations where people couldn’t get to or were considered too dangerous. However, this is changing, says Barry McGinn, sales director, Capital Projects, Cyberhawk.

“The role of drones is evolving, and they are now being deployed to survey the progress and performance of a project. They’re enabling stakeholders to monitor the site from anywhere in the world,” he comments.

“Drone survey images are now at the same level as terrestrial surveys, but the benefit of drones is that up to 30 times more distance can be covered in a day. The efficiencies that can be made are astronomical. We also now have drones operating with what’s effectively a force field around them, enabling them to fly indoors through structures without risk of collision. This allows for the collection of incredible imagery, giving a photo-realistic view of assets.”

How to use drones in construction

That construction is not the world’s most efficient sector is well known – the industry’s relative lack of productivity gains has been well documented. In order to become more productive and efficient, it first needs to be known what work has taken place; this is where drones and the data they collect are essential.

Collecting data on a site makes it possible to track progress over time to enable project stakeholders to see what areas could become more efficient and also the optimum time for materials to be moved. Swiss-based software company Pix4D is one such company that offers these services.

“PIX4Dcloud Advanced allows constructors to use its timeline feature to track changes over time. The workflow is very straightforward: collect data via drones or mobile devices, process it online with PIX4Dcloud, and then analyse the site,” says Gabriele Ruggiero, business development manager, AEC Solutions at Pix4D

“You can measure distances or volumes, share 3D models, and monitor stockpiles. To track and manage progress, the timeline tool allows you to overlay design plans and maps in order to identify errors early and avoid expensive rework. All of this can be shared online with stakeholders via links as it is hosted online, which means processing and analysis can take place off-site.”

Using drones and software enables firms to document their progress. It means they no longer have to guess how long it takes them to move material – they know exactly. “Drones not only give you great pictures, but you have data you can measure with, like areas, your footages and volume metrics,” says Jason Anetsberger, director of customer solutions at Komatsu. “That data can become the truth for the job site.”

During a preconstruction flight it is possible to compare the real site to the engineer’s model, which allows for any miscalculations to be fixed.

“We had a customer recently who realised they had to move 40,000 cubic yards more than what the engineer quantities were saying they needed to do at the beginning of the job,” comments Jim Petry, Smart Construction solutions manager.

“For them, that was a big revelation. That was the first time that they used a drone. They quickly found a lot of value in it. They can see where their cut and fills are on the site, where that is taking place, and if it’s a large site, they can make better decisions on equipment.”

Future applications of drone technology

The potential of this technology goes even further than monitoring – and optimising – a construction site. One of the ways it can be used is to help create and update 3D models.

“This feedback from the field leverages multiple techniques, but companies are now making reality modeling and surveying an essential component of this process, with an increasing adoption of 3D laser scanners, drones, timelapse cameras, and photogrammetry,” says Bentley’s Martinez.

“Moreover, surveying is not only used to monitor progress and control the quality of the construction, but also to create 3D snapshots at key project milestones, that can be archived and reused during maintenance and operations. It is also used to update design models to keep digital twins evergreen and improve the communication between designers and constructors.”

At the moment, in most countries, a drone can only be flown to a point where they remain in the pilot’s line of sight but that may change, says McGinn from Cyberhawk. “I believe we’ll eventually shift to remote flying, which will be transformative in terms of productivity for linear civil engineering projects like roads and railways,” he says.

In addition to this he believes that “In the next five to ten years, we’ll see widespread use of drones for delivery, supporting modern methods of construction. Site data gathered by drones will alert off-site manufacturing assets when facilities such as bathroom pods or heating, ventilation and air conditioning systems are required, and drones will be used to deliver those materials at the right time.”

Construction is a fractured industry, with just one large-scale project commonly having numerous contractors and even more subcontractors working on it. Multiple stakeholders can make sharing data difficult but, says Pix4D’s Ruggiero, “Construction platforms are also becoming more straightforward to integrate with, which helps us to support our clients that work with multiple products and service providers.”

Another potential change could be the move towards LiDAR, which uses the light from a laser to collect measurements. At the moment most drones use photogrammetry, which provides consistent ground models. Trimble’s Greenberg says LiDar has advantages, but a change won’t happen for a little while yet.

“When you are flying a drone with LiDar, it has lots of advantages – it can penetrate foliage, but you have to have really accurate orientations and the accuracy just isn’t as good as what we can get out of photogrammetry,” he says.

“If the price point was right and the LiDar was good enough, I’m sure we’d have all drones with LiDar and photos, so maybe five or ten years from now. But I don’t see LiDar taking over from photogrammetry for our applications in the near future.”

There will doubtless be changes to both the physical drones themselves and the software in the future, as well as to how the data is used. One thing that will remain constant though is this branch of construction technology being used to keep the ‘real’ world and the digital world in step. For example, a drone flight on a Sunday night will provide accurate data for a whole team on Monday morning about the exact state of a project.

As Greenberg says, “the real and digital world go out of sync all the time. When you see that the real and digital world are diverging, it’s a way to pull them back together.” As the influence of the digital world grows ever more in construction, having the ability to make sure that this world and the ‘real’, physical world are the same will only grow in importance.

Drone manufacturer Skydio has announced the launch of its new product line, which includes Skydio Dock and Skydio Dock Lite, powered by Skydio’s new Remote Ops software.

US-based Skydio says that its Dock solutions give users complete remote and autonomous visibility into tasks like site inspection and monitoring, mapping, and situational awareness.

Skydio drones housed in Dock and Dock Lite can fly safely with a single off-site operator, or autonomously. Skydio Remote Ops software is said to enhance the drone’s AI-powered autonomy so operators can perform streamlined missions.

Adam Bry, CEO of Skydio, says, “Skydio Dock and Skydio Dock Lite, combined with our Remote Ops software, deliver autonomous capabilities for our customers, whether they are monitoring their warehouses, inspecting a security perimeter, or assessing infrastructure following a natural disaster – finally realising the promise of efficient, scalable remote operations.”

This announcement is made with the participation of Skydio’s Early Access customers and partners, such as the North Carolina Department of Transportation, Southern Company, Caltrans, the Oracle Innovation Lab, and Japan-based Obayashi Construction.

Time compiled the list via solicited nominations from its editors and correspondents around the world, and through an online application process. The company then evaluated each contender on a number of key factors, including originality, efficacy, ambition, and impact.

Hexagon says that the BLK2FLY can quickly and accurately capture everything from large outdoor spaces to complex structures and environments. The resulting colourised 3D point clouds are instrumental in building information modeling (BIM) processes, documenting site conditions, and improving any asset’s operation.

“Having our reality capture technology recognised by Time as one of the year’s best inventions is both humbling and inspiring. It validates our mission to build Smart Digital Realities that empower an autonomous, sustainable future,” says Hexagon President and CEO Ola Rollén.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM