Read this article in Français Deutsch Italiano Português Español

The risk of noise in construction and new ways of protecting workers from it

22 April 2024

Image: Tomasz Zajda via AdobeStock - stock.adobe.com

Image: Tomasz Zajda via AdobeStock - stock.adobe.com

Construction sites are noisy places but it’s still a startling statistic that more than one in 10 US construction workers (14%) have hearing difficulty.

That’s according to official figures published by the National Institute for Occupational Safety and Health (NIOSH), the US federal agency responsible for preventing work-related injury or illness.

NIOSH also reports that 51% of all workers in the sector have been exposed to hazardous noise, while more than half (52%) of those exposed to noise reported not wearing hearing protection.

It’s perhaps little wonder that 25% of noise-exposed construction workers who were tested have a material hearing impairment.

So, as International Noise Awareness Day approaches on 24 April, what can the sector do to improve both the protection employers offer to workers and increase awareness around the issue?

Is protection fit for purpose?

Hearing protection has been available to construction workers for years but having protection that is fit for purpose, is being used properly for the appropriate amount of time, and fits well is a more complex issue.

Eave’s Focus Lite helmet-mounted headset (Image: Eave)

Eave’s Focus Lite helmet-mounted headset (Image: Eave)

“The risk of injury from prolonged noise exposure has been public knowledge for decades, and the use of hearing protection on construction sites will be commonplace. However, for employers to ensure that they are not risking damage to employees’ hearing and to guard against future claims, the hearing protection they provide must provide sufficient attenuation,” says Chris Gower, an insurance lawyer at international law firm RPC.

“Not only does this require an assessment of the likely noise being produced by equipment and machinery to choose the right ear plugs or ear defenders, but the use of hearing protection must be properly enforced. Training should also be provided on how to wear hearing protection properly as the incorrect fitting of earplugs reduces the protection given.”

While it concerned military personnel, rather than construction workers, these considerations came to the fore when service members and veterans in the US sued 3M, alleging that the earplugs it manufactured were defective and led to hearing damage from loud sounds on the battlefield.

Plaintiffs in the lawsuit claimed that the company hid design flaws and failed to provide instructions for the proper use of the earplugs, leading to hearing damage. 3M ultimately settled the lawsuit in August last year for $6 billion without making an admission of liability.

Meanwhile, the UK’s Health and Safety Executive (HSE) has this month launched a campaign that will see its inspectors focus on noise as part of their interactions during visits to 3,500 to 4,000 different sites across all industries over the next two quarters.

“This is the first time in about a decade that we’re targeting noise as an issue and we’re specifically targeting around hearing protection,” HSE principal inspector and noise expert Chris Steel tells Construction Briefing.

It’s the first phase in a multi-phase process that will see inspectors check on the quality of hearing protection and how it is being used. Phase two, scheduled for 2025 will then focus on control measures, with more targeted inspections on sites where inspectors are aware that there are noise issues or instances of protection not being used well.

The HSE is encouraging employers to follow the acronym ‘CUFF’ when assessing measures to reduce risks of exposure to noise. That stands for: Condition (Is the hearing protection in good condition?); Use (are workers using protection all the times they should be?); Fit (does the protection fit the wearer?); and Fit for purporse (does the selected hearing protection give the right level of noise reduction?).

Commenting on the campaign, Dr. David Greenberg, a clinical and research audiologist who founded smart hearing protection brand Eave says, “It’s kind of unprecedented. While that’s a UK initiative, I’m pretty sure it will start to be adopted on a more global scale.”

Comfort and fit crucial

Such legal and enforcement actions are making employers wake up to the importance of providing workers with adequate protection, says Paul Jobin, founder of Snugs, which provides custom-fitted silicone earplugs.

A worker wearing Sungs’ ear protection (Image: Snugs.com)

A worker wearing Sungs’ ear protection (Image: Snugs.com)

“There are 55 million people at work today in European and North America exposed to over 95 decibels - that’s the problem,” Jobin says.

“Just to put that in perspective, health and safety laws in Europe say that you shouldn’t expose a worker to more than 80 decibels. At 95 decibels, you exposure time is about 47 minutes and after 47 minutes, you are potentially damaging your hearing.”

And he comes up with another surprising statistic – if you only wear your hearing protection for 95% of the time that you are exposed to excessive noise levels then the effective rating of that hearing protection is halved.

That is where, he argues, comfort and fit become very important.

“If you have a foam earplug, you have to screw it up and stick it deep in your ear. People don’t tend to do that. You have to find a solution that is comfortable. A lot of people will use ear muffs – in construction ear muffs are very common. People clip them to the side of their hard hats. But how many people actually wear them?,” he says

“Workers need to be wearing it correctly. What does correctly mean? Do people ever read instructions when they are issued with these products? Does anybody show them how to put them in? I would argue not. We are engaging with tier-one construction companies – they are the ones who have a higher liability and therefore a higher desire to do the right thing and drive the message through,” he adds.

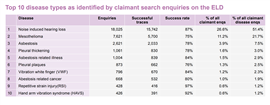

Top 10 occupational disease types based on claimant search enquiries on the Employers’ Liability Database in the UK (Image courtesy of UK Health and Safety Executive)

Top 10 occupational disease types based on claimant search enquiries on the Employers’ Liability Database in the UK (Image courtesy of UK Health and Safety Executive)

‘Buy quiet’

“Construction is an industry where there is a lot of will to improve and where improvements are happening,” says Greenberg.

Given the level of noise that tools and machinery used in the sector can generate, he advocates a ‘buy quiet’ policy in the first instance. That means companies checking product information sheets to select products that produce the lowest level of noise for workers to use.

But he adds, “Unfortunately that can only go so far. Because actually the noise generated has much more to do with the way that it’s being used and the way that it’s being maintained.”

“We do know that construction has an issue in terms of trying to deal with workplace noise,” says Steel. “Talking as an inspector, if I go to a construction site and they are wearing hearing protection, it is usually too late in most cases to change the activity or change the process in order to reduce the noise. The decision for a certain machine to be on site or for a certain method of construction was made months or even years ago at the design stage. So we way we tend to deal with workplace noise on construction sites, with some exceptions, is to say: ‘We know it’s noisy. What are you going to do about hearing protection? And then the next time you come to build this type of project, we want you to think about different ways of doing it’.”

“The construction industry has a difficult task but a lot of noise is generated around the use of power tools. They only way you are going to see a significant change there is through modern methods of construction and offsite construction,” he adds.

Jobin thinks that driving greater awareness among workers, along with greater efforts by employers to offer higher levels of protection to them along with clearer guidelines on how to use it is the way forward.

More sophisticated solutions

A problem in the past with offering workers a more comfortable, custom-fitted ear plug was one of time and resources. Normally it required either for workers to go to an audiologist to create a physical impression of their ear or for the audiologist to come to site.

But that obstacle can now be solved with the use of a smartphone, Jobin explains. “We are able to take a single, 2D image with a smartphone and create certified, custom-fitted hearing protection” he says.

Image: Tomasz Zajda via AdobeStock - stock.adobe.com

Image: Tomasz Zajda via AdobeStock - stock.adobe.com

Meanwhile, Eave’s product incorporates digital technology that not only protects workers’ hearing but also allows employers to monitor a range of different metrics to monitor workers’ exposure levels and whether they are actually wearing the protection.

Eave’s headsets are designed with ‘hear-through’ technology that eliminates the need for a site worker to remove them in order to hear sound around them or talk to colleagues.

“Microphones on the outside of the ear defender allow you to still hear naturally where things are at a safe level. If sound is really loud the ear defender will kick it down to the right level of protection. But if a sound in the environment is really low it can boost them so you can hear them at a safe level or just let them through in a very natural way,” Greenberg explains.

“The ear defenders are actually monitoring the amount of noise reaching a person and they’re doing a comparison of the noise in the environment to the noise on the inside of the ear defender. And using those measures you can judge whether it is being used correctly and whether it is fit for purpose and providing the right level of protection against what is in the environment,” he adds.

Using Eave’s Peak management platform, which takes the data from its Focus Lite headsets, the system can provide digital site maps overlaid with noise levels at different parts of the site, eliminating the need to monitor noise levels manually. That allows dutyholders to understand where they need to create mandatory hearing protection zones and where to focus on reducing noise at source. The system will also send out notifications when workers are not wearing protection or when a person exceeds the allowable limit of 85 decibels (in the UK) in a moment or over time (85 decibels for eight hours).

Cost argument

Of course, more sophisticated solutions don’t necessarily come cheap. And while tier one contractors like the Skanska/Costain/Strabag joint venture (SCSjv), the main works civil contractor on the UK’s HS2 high-speed rail project, have the budget to invest (SCSjv ordered 300 Eave headsets for the project), smaller companies may not feel that they do.

Greenberg concedes that this is a challenge. “There are very logical reasons for large contractors to protect people’s hearing. There’s a moral reason, they don’t want to deal with the fines and the insurance issues, and they have the budget as well,” he says.

Beyond their legal responsibility for the health and wellbeing of their employees, large contractors also tend to recognize that having people retiring earlier than they might otherwise have done due to hearing loss exacerbates the skill shortage, and having people go off sick hurts productivity, he points out.

But for small organisations and the self-employed, it is more heavily weighted on the moral and health factors, he says.

But he argues, “You can either pay £250 (US$316) for a smart ear defender, or you can spend £1 (US$1.30) a day for a few pairs of foam ear plugs. Over the course of two years, you are still better off with a one-off solution or smart ear defender than constantly paying for single-use plastics. For the smaller firms and self-employed contractors, it is a bit of a false economy not to invest in proper equipment.

“But there is a cultural difference - the large organisations are triyng to achieve best practice. Some smaller contractors and individuals are going to be very health conscious and protect themselves. For others, it is barely even an afterthought, sadly. And ultimately they end up paying the price through their own health.”

Common signs of hearing loss

Some of the most common signs of hearing loss are:

- Difficulty hearing other people clearly

- Trouble hearing whilst on the phone

- Misunderstanding what is being said, especially in noisy places

- Asking people to repeat themselves

- Withdrawal from conversations

- A reluctance to socialise

“Hearing loss can make it more tiring to communicate in day-to-day situations, leading to increased fatigue, headaches and irritability. It can lead to people withdrawing from social situations they previously enjoyed, as it can make them feel isolated and unable to take part in conversation,” says Charlotte Chappell, audiologist at Boots Hearingcare.

“Untreated hearing loss has been linked with depression, anxiety and conditions such as Alzheimer’s, primarily because it can increase isolation and make social interactions more challenging. Seeing an audiologist and getting a free hearing test is beneficial even if you don’t feel you have any difficulty with your ears or hearing.”

|

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM