How far are we into construction’s autonomous pathway?

21 September 2023

Construction’s path to autonomy is underway and, while a fully autonomous jobsite is far away on the horizon, the benefits of this technology are being felt today, writes Andy Brown.

Construction has long held a reputation – often justifiable – of not being the quickest of industries to adopt new technologies and methods of working but, at least when it comes to autonomy, that could be changing.

Data from an autonomous mining truck shown on a digital tablet (Photo: Adobe Stock)

Data from an autonomous mining truck shown on a digital tablet (Photo: Adobe Stock)

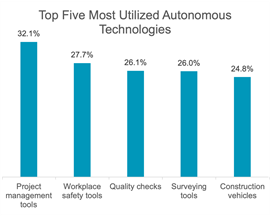

This view is given weight by a survey from Hexagon, specifically on Autonomous Construction Tech. The survey of more than 1,000 technology decision-makers from general contracting firms of all sizes across North America, the UK and Australia revealed that 84% of firms have already adopted autonomous technology at some level.

Of these, the majority report clear benefits, ranging from sustainability improvements and waste reduction to improved safety compliance. In addition, the construction firms surveyed plan on investing an average of US$7.1 million in autonomy within the next three years.

“Construction firms are turning to autonomous solutions to mitigate risks better and improve the effectiveness of operations, which are both key to overcoming the productivity, sustainability and profitability issues they face every day,” says Thomas Harring, President of Hexagon’s Geosystems division.

The benefits that autonomy can bring are clear: autonomous tech makes jobsites safer, more efficient and sustainable. A key way it does this is by what Harring refers to as the ‘data leverage gap’. He explains this as, “that ever-widening chasm that exists between the data created during the lifecycle of a project and the data actually used to produce meaningful insights, outcomes and opportunities for growth.

“Autonomous technology is transformative technology that will define the next era of construction. The key right now is to help the industry leverage technology in a way that ensures optimisation and lasting, scalable results.”

Different stages on the autonomous journey

Autonomous equipment is increasingly being tested on construction sites across the world

Autonomous equipment is increasingly being tested on construction sites across the world

Autonomy isn’t binary; something isn’t either not autonomous or fully autonomous. There is a whole spectrum of semi-autonomy, of which the technology has long been used in the form of machine control and the automation of some process in the construction cycle.

In fact, there are generally considered to be five levels autonomy – from level one where the operator performs most tasks with some basic AI guidance, to level five where the machine operates with full autonomy, doing anything that an experienced human operator could achieve. So, where is construction on this continuum?

“We’re seeing a lot of spectrum between Level one and three, across a lot of vehicles, with a bigger push toward Level three, in construction specifically,” says Peter Bleday, head of autonomy at Danfoss Power Solutions. “The reason for this is an increasing lack of experienced labour, let alone a lack of labour in general. Rework, quality of work, things that are costly to a contractor; if you can add some capability onto the vehicle, you can give the vehicle that five years of experience that you don’t have with a novice operator. There’s a lot of value around driver assist technology.”

Regardless of what level of autonomy is being used, what is key is that it is providing tangible benefits, agrees Scott Scheffler, Moog Construction’s marketing manager. “There are increasing levels of autonomy, from augmented operation to full autonomy. All along the way, it’s critical to introduce technology that improves productivity while working safely with people.”

Autonomy can mean a task being done by a piece of equipment – such as an excavator with machine control digging to a depth of 30m automatically – or processes being done by a machine rather than a person, such as the reformatting and organisation of data. These processes may be less eye-catching than a 20-tonne machine moving by itself, but they are just as important, if not more.

“When you’ve got the design and you’re doing costings and bidding, a lot of the times things are just fed over on paper plans and contractors are having to redigitise and create a model when it already exists,” says Cameron Clark, Earthmoving Director for Trimble’s Civil Infrastructure Solutions Division.

“It sounds simple but so many people are complaining that, ‘I’m getting all these paper plans, I’ve got to spend time recreating, redigitising, remaking all these models.’ When you’ve got people involved doing that you get errors. Having a process that can automate taking it in and pulling the information that they don’t need out saves time.”

Impact of autonomy in construction today

Construction is a much harder industry in which to automate equipment due to it being more ‘dynamic’ than other sectors, such as mining. There are more moving parts and different equipment on a construction site and it may also only be there for a short period of time. Despite this, autonomy has already impacted equipment used on sites around the world on a daily basis, such as bulldozers.

Almost all bulldozers now produced come with grade control as automatic and this means that contractors can use them slightly differently, and even eliminate the usage of some machines. “Maybe before you’d have a dozer work and a grader would finish it, clean it up. Now you don’t necessarily need the grader to finish it,” says Clark. He adds that on many sites machine control on excavators means that they can do work on slopes where previously bulldozers would have been used, freeing up these machines to do other work.

Cameron Clark, Earthmoving Director for Trimble’s Civil Infrastructure Solutions Division

Cameron Clark, Earthmoving Director for Trimble’s Civil Infrastructure Solutions Division

“Adoption is growing and then, as we add more value, it’s around people understanding it to make sure it’s going to fit in their workflows,” adds Clark. “It’s a good business to be in at the moment because we all have to do more with less, and this is what we do. A side effect is sustainability, which is awesome, as the technology enables us to do things quicker, cheaper, and faster.”

Humans remain key

A point all of those involved in this technology make is that – for the foreseeable future – humans will remain central to the process of automation and the technology is there to make their lives easier, not to replace them.

Construction sites are typically dynamic and quickly changing, making full automation of equipment extremely difficult. It is likely that the first fully autonomous machine that will be used on working construction sites is the roller; compaction is very important, but it is also straightforward, with a machine moving in a straight line to set parameters. Trimble recently announced that its autonomous roller has been successfully trialled on a working jobsite in Canada, but there is no date for when this might be commercially available.

Rather than thinking about machines being automated it makes more sense, suggests Trimble’s Clark, to focus on workflows being automated. “Fully autonomous sites with no people are a long, long way away. What’s more realistic is there are going to be certain workflows and machines doing certain tasks that it makes sense to automate.

“We’re not going to be able to automate everything and it doesn’t make sense to even try to do that. Our autonomous workflows are all sitting on top of Trimble Earthworks, where the machines have got a system where they can provide guidance and automation for operators. You can put in your complex design, and the operators do that. Then, if the machine needs to dig a 200m trench the machine can be tasked to do it in an autonomous workflow. It’s not an autonomous machine; it’s an autonomous workflow.”

This point is echoed by Bleday. “Don’t think necessarily about automating the machine but think about all the tasks a machine can do and automating those,” he says.

“In construction, you have excavators, skid steers, compact track loaders, wheeled loaders, etc, that are utility vehicles – they don’t just do one task, they do many. So, while there are some vehicles, like a soil compactor or a double drum roller, that might be more single-task oriented, that’s not often the case in construction.”

How can we adapt to new technology in construction?

Autonomous machines are more common in mining than in construction

Autonomous machines are more common in mining than in construction

Regarding equipment, Moog – which works with OEMs including Bobcat, Komatsu, and Case – suggest that owners and operators being able to adapt as the technology progresses is key. “To design automation solutions for construction, engineers must consider the consequence of failure, which depends on the machine’s environment and application,” says Scheffler.

“The smart path is building vehicles with a control platform that owners can easily adapt and evolve as technology and industry processes adapt.”

Being able to evolve with new technology is obviously key but Clark says that fully autonomous equipment is not something that we will see for a long time. “When I see these machines with no cabs and other things, I just cringe because that’s a long, long, way away. People are critical, they do the complex things. We need operators; we’re just going to use them a little bit differently.”

The idea of a construction site with machines operating autonomously is, for now, science fiction. However, the technology that is being used now to automate machines, data and processes, would also have been unthinkable a few decades ago.

It is also clear that, as the industry takes its steps on this path, there are significant benefits that will be delivered along the way such as sustainability, increased productivity and efficiency and being able to do more with fewer people and machines.

Semi-automation and sustainability

A new report from Topcon, The Future of Machine Control, explains how machine control technology can help reduce emissions.

The survey of around 1,000 managers across the European construction industry revealed that 67% of respondents agreed that construction would hit net zero by 2050 – but 30% still highlighted hitting sustainability targets as a key challenge on projects. Machine control is a significant step that construction businesses can take towards greener operations.

Companies are under pressure from soaring material costs, shrinking margins, combined with increasingly strict environmental regulations. Senior vice president, Topcon, EMEA, Luc Le Maire, says that machine control can provide a solution to these issues. “Machine control can be a game-changer – the improvements in demand from clients mirror those most selected as the main benefits of machine control in our research, with accuracy and improving efficiencies both chosen by a quarter of respondents,” he says.

“Combine that with the fact that machine control emerged as the joint most selected factor for meeting future sustainability goals, and the consensus is clear – a more efficient and accurate industry is a more sustainable one. A lot needs to change before construction hits net zero, but machine control can be a crucial catalyst for construction companies looking to reach higher levels of accuracy and efficiency, deliver lower carbon footprints for clients, and submit healthier sustainability reports.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM