New AI quality control system for construction

30 June 2021

Technology, such as AI, can boost construction’s productivity

Technology, such as AI, can boost construction’s productivity

A joint artificial intelligence (AI) solution has been launched for the construction industry by testing, certification, and inspection company TÜV SÜD and UK-based construction analytics firm Contilio.

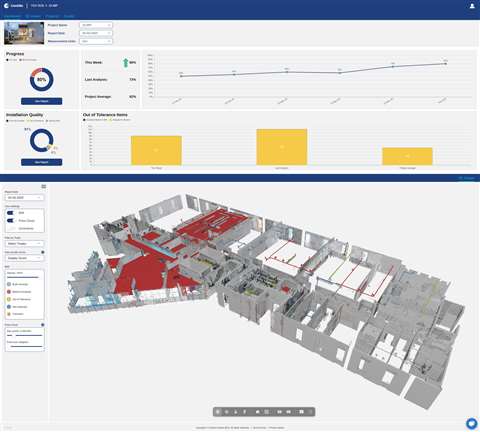

The 3D AI Construction Inspection system will provide automated defect analysis, installation quality verification and progress tracking for building and infrastructure construction projects.

According to the companies, the solution enables asset owners, general contractors and investors to deliver projects within the time, cost and risk requirements.

“Shockingly, 60% of all construction projects experience significant delays, and up to 30% of construction costs are swallowed up by the need for rework and installation error rectification”, says Joachim Birnthaler, CEO of TÜV SÜD’s real estate and infrastructure division.

“In addition, more and more owners, developers, and investors are seeking to maximise the quality of their construction projects, delivering them more sustainably and with reduced carbon footprint.”

Digital methods such as Building Information Modelling (BIM) and Digital Twins can help to deliver construction projects with improved productivity, sustainability and delivery timeline as well as reduced costs.

The AI works with commercially available Lidar scanners and drones and helps to automatically track construction progress and installation quality for both building and infrastructure projects. This automated comparison can also help keep digital twins up-to-date during the construction and provides the opportunity to rapidly detect any deviations from plans or installation errors.

Zara Riahi, CEO of Contilio added, “Our solution combines advanced 3D AI technology with 150 years of global inspection and testing expertise to automatically provide actionable intelligence from 3D construction site data (Lidar/Laser scans) in real-time.

“This is done by intelligently identifying all structural, architectural, MEP and fitout elements in 3D site data, and then automatically comparing them with the BIM and the schedule.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM