Read this article in Français Deutsch Italiano Português Español

Skyline Scaffold engineers award-winning solution

21 May 2024

Skyline Scaffold Ltd. combined multiple elements into one cohesively functioning scaffold system in order to replace a skylight over an active building lobby – and took home the SAIA Project of the Year Award for Innovation for its work. SA reports.

When Skyline Scaffold Ltd. was contracted by Matra Construction to develop a solution to handle a skylight replacement over an active building lobby in the Justice Institute of British Columbia, in New Westminster, B.C., the company had to think outside of the box.

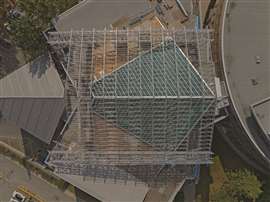

Skyline Scaffold built temporary support towers to facilitate the building of its modular SkyTruss system to support the roof. The towers were removed once the roof was in place. (Photo: Skyline Scaffold)

Skyline Scaffold built temporary support towers to facilitate the building of its modular SkyTruss system to support the roof. The towers were removed once the roof was in place. (Photo: Skyline Scaffold)

The project required a system that did not load the existing roof, while also being wide enough to span the 100-foot, two-way sloping roof.

After reviewing site conditions and assessing the challenges posed by minimal roof-loading capacity, a clear span solution was found to be the only viable approach to redistribute loads from our system, workers and materials to the exterior walls instead via gantries on either side using our patented SkyTruss system, which is the lightest and strongest unit beam on the market, according to the company.

SkyTruss cantilevered out to allow the Layher Keder roof to extend past the building face without supporting it from the ground. (Photo: Skyline Scaffold)

SkyTruss cantilevered out to allow the Layher Keder roof to extend past the building face without supporting it from the ground. (Photo: Skyline Scaffold)

A Layher Keder roof of approximately 100 feet by 100 feet was mounted over the company’s patented SkyTruss gantries on each side of the roof to create a load path through exterior shear walls and columns. Skyline Scaffold also constructed a large internal area platform to provide access to the underside of the skylight in addition to public protection.

“One of the many challenges was limited crane staging areas on the property,” the company noted. “Our SkyTruss system solved the issue of creating a span of this length with the significant loads of a large temporary roof and, being largely modular, we were able to construct it ‘in situ’ using 1m, 2m and 3m sections that were easily built by hand.”

Load-bearing considerations

The project involved combining multiple elements into one cohesively functioning scaffold system in order to span a two-way sloping skylight, all without loading the existing roof.

A 100-foot by 100-foot Keder Roof loading a 100-foot-long span of SkyTruss, picked up on the four corners. (Photo: Skyline Scaffold)

A 100-foot by 100-foot Keder Roof loading a 100-foot-long span of SkyTruss, picked up on the four corners. (Photo: Skyline Scaffold)

The interior scaffold was designed to provide a large span public protection deck using Layher 750mm over 750mm beams over an active diamond-shaped lobby that also provided access to the underside of the skylights for the glazers.

On the exterior, a clear span weather protection system was required that had to be low enough to prevent wind-driven rains from entering from the sides. Additionally, it had to load paths to the exterior of the building as the existing design loads were too low to allow any scaffolding to be built on the roof.

Engineering processes

“We delivered a very sophisticated and innovative engineering package using many ‘firsts’ in North America and very little in terms of ‘off-the-shelf’ systems,” Skyline said. “After evaluating load paths, our SkyTruss system was determined to be the only viable solution, as steel beams would have been extremely heavy and costly at 35m long, and would have been impossible to place, given the lack of staging area for cranes.”

The temporary towers used to stick build the modular Skytruss. (Photo: Skyline Scaffold)

The temporary towers used to stick build the modular Skytruss. (Photo: Skyline Scaffold)

It was determined the SkyTruss gantry had to be reinforced and doubled as a result of side loads imposed from the 100-foot clear span Keder roof.

“SkyTruss can not only be double-, triple- and quadruple-chorded, but it can be stacked as well in all four configurations,” the company said. “Our in-house engineering team worked diligently with our project managers in collaboration with base-building engineers to design support towers in only four areas to resolve dead and live loads, as well as wind loads up to 90km/hour.”

The Scaffold & Access Industry Association’s Innovation Project of the Year award is presented to a member company that:

- demonstrated a new or innovative way to utilize an existing product on a project, or

- delivered a new product to the field.

For more information, or to enter this year’s awards, visit www.saiaonline.org.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM