Read this article in Français Deutsch Italiano Português Español

Strabag claims new modular housing system could cut CO₂ footprint by 50%

15 August 2025

Strabag introduced TETRIQX, a serially-produced modular building system designed to cut construction-related emissions and reduce build times.

Render of a housing complex designed with Strabag’s new TETRIQX modular building system. Image: Strabag

Render of a housing complex designed with Strabag’s new TETRIQX modular building system. Image: Strabag

The Austria-based construction contractor estimated the system can reduce CO2 emissions up to 50% over a project’s life cycle while cutting construction timelines by as much as four months compared with conventional methods.

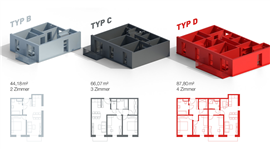

TETRIQX is based on high-prefabrication modular units and offers three pre-planned residential building types, each optimised for floorplans of about 44–88m². The designs can also be added on top of existing residential buildings up to seven storeys high. Strabag said the approach enables standardised, high-quality construction that can be scaled for urban infill projects.

Emission reduction measures include the use of sustainable materials in production and concrete core activation, which allows efficient heating in winter and passive cooling in summer without added construction cost. Strabag believed this could reduce heating and cooling energy demand during operation by at least 22%.

In addition to sustainability and construction timeline advantages, the company said the system can deliver residential units from €1,950/m² (US$2,284/m2); a price point it said could help revive investment in Austria’s strained affordable housing sector.

First projects are expected to break ground in 2026.

Digital representations of the TETRIQX modular units. Image: Strabag

Digital representations of the TETRIQX modular units. Image: Strabag

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.

CONNECT WITH THE TEAM